|

|

The FOUR T BROS di Vanio Tessaro & c. s.a.s. located in Montebelluna, Treviso, Italy, is producing the heat sensitive selfmolding "Heat'n'fit" material.

Its main features are:Easy-to-use, the melting temperature is 70 degree Celsius, which can be reached through a home oven (no micro-wave) or through an hair drier.

Once fitted, the material keeps the shape for ever, unless it is heated again.It's lighweight, in fact most of the volume is given by natural cork.

It doesn't collaps, because it is made with not-expanded materials apart from cork, which is compressing only with high pressures and when released it come back to its original volume.

There is no limits on how many times you can heat and fit it, because it reacts like a thermoplastic material.

It is completely free from noxious or toxic materials.

No need of any kind of glue when assembling, because the selfmolding material is itself very sticky.

|

The outcome of all this is a selfmolding material which can be used for custom fitting products which must adapt to the wearer's body parts to distribute the pressure in the widest area,

for sport items where sensitivity and feeling is requested like ski, snowboard, soccer, golf, bike, skate, inline skate,

and all the static situations, like people which are standing all day long.

The Heat'n'fit selfmolding material can also be used for customizing motorbike seats, horse saddles both sides

(rider and horse), arms and head supports, etc.

The limits of the fields of employment of the product is only given by the limit of the fantasy.

|

|

Foam material usually used for paddings.

| Heat sensitive Heat'n'fit selfmolding material.

|

|

|

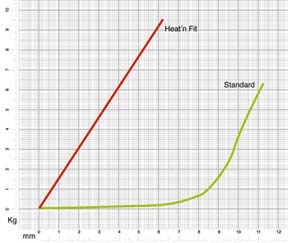

The chart is showing the different compression behaviour between a commonly used foam material

and the heat sensitive "Heat'n'fit" selfmolding material.

Most foam materials (green) behave all almost the same way:

at the beginning of the compression the volume is shrinking opposing a weak resistance. In other words it means that

the limb (foot, elbow, arm, bottom, or whatever, is supported mainly by the prominences, while the rest of the limb is unloaded.

On the contrary, the heat sensitive Heat'n'fit selfmolding material (in red), with the encreased pressure, is opposing a

higher and higher resistance, and since it is molded on the wearer's limb, the pressure is shared on the maximun surface.

|

The heat sensitive "Heat'n'fit" selfmolding material can be supplied in shaped pieces or in square slabs in different thicknesses which can be cut with dies or with a pair of scissors.

| |

|